The fast-paced evolution of technology has continuously redefined multiple sectors and the food manufacturing industry is no exception. One of the areas of innovation is in the liquid packaging processes. Liquid food products, whether sauces, beverages, or dairy items, require specific packaging techniques to ensure safety, longevity, and aesthetic appeal. This article delves into the future of liquid packaging, specifically focusing on the rising influence of automation.

Understanding Automation in Liquid Packaging

Automation in liquid packaging represents a transformative shift in the food manufacturing industry. By utilizing cutting-edge technology, these automated systems significantly increase production rates, ensure consistent packaging quality, and reduce the risk of workplace accidents. This paves the way for higher output, increased profitability, better product quality, and a safer working environment, positioning it as a vital component of the industry’s future. Here are the benefits of automation:

- Improved Efficiency: Automated packaging machinery is designed to perform tasks at high speeds with minimal human intervention. This translates to increased production rates and efficient utilization of resources.

- Enhanced Accuracy: Automation significantly reduces the likelihood of human errors, ensuring consistency in the volume of liquid-filled, seal quality, and packaging weight.

- Worker Safety: With automation handling high-risk tasks, workers are less exposed to dangerous conditions, reducing the potential for workplace accidents.

Innovative Trends in Automated Liquid Packaging

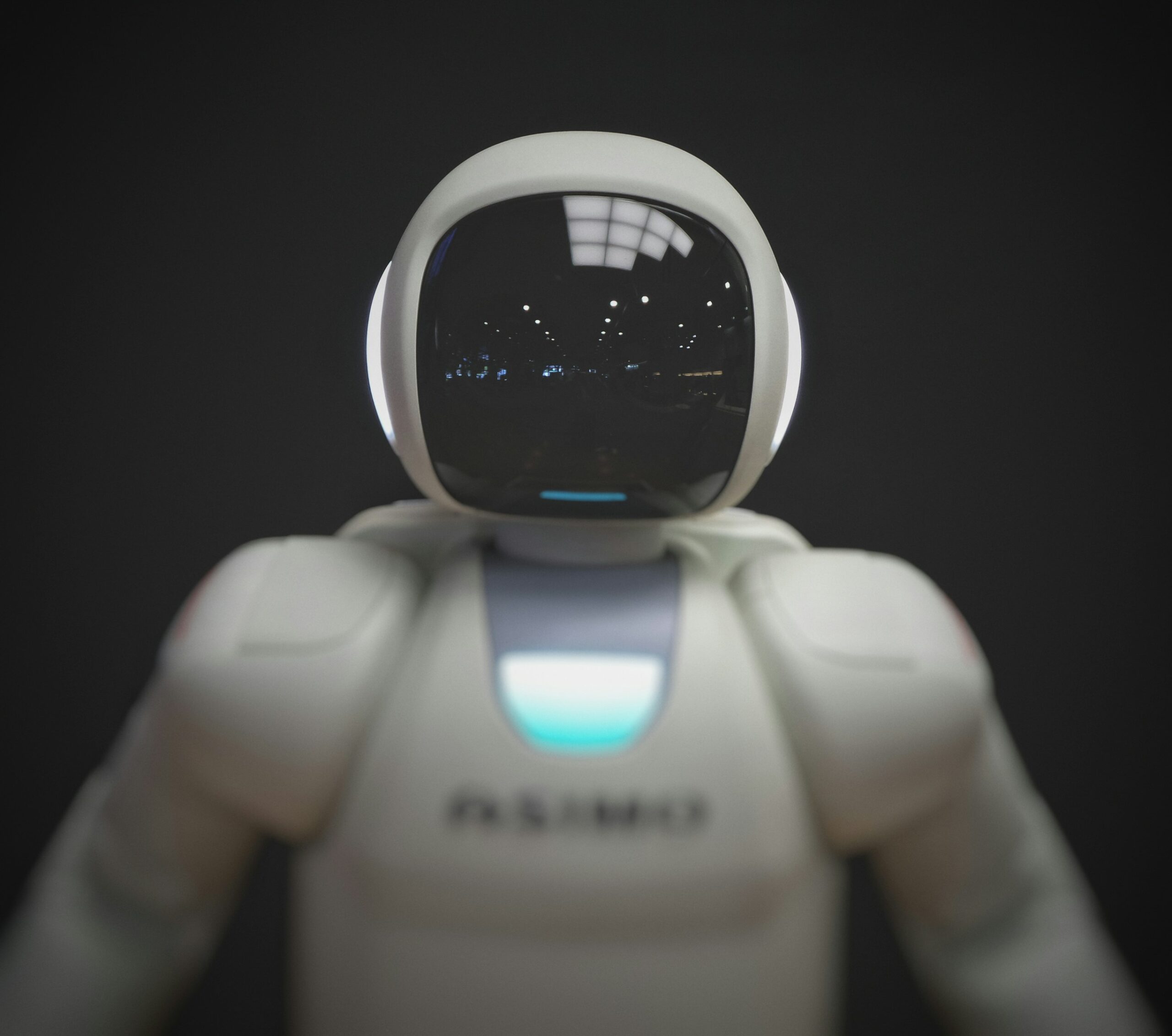

Innovative trends like the integration of Artificial Intelligence (AI) and Machine Learning (ML), increased use of robotics, and a greater emphasis on sustainability are set to redefine the landscape of liquid packaging in the food manufacturing industry. Here’s how these technologies will impact the future of liquid packaging:

- Integration of AI and Machine Learning: Artificial Intelligence (AI) and Machine Learning (ML) can optimize various aspects of liquid packaging, such as predictive maintenance, quality control, and process optimization. These technologies can enable predictive algorithms that foresee equipment failure, saving downtime and maintenance costs.

- Use of Robotics: The adoption of robotic arms in packaging lines will increase. Capable of performing complex tasks with precision and speed, robotics will handle everything from capping bottles to arranging packaged products on pallets.

- Sustainability: Automation will enable the efficient use of resources, reducing waste and environmental impact. It will also allow the implementation of innovative, sustainable packaging materials that would be challenging to handle manually.

Implications for the Food Manufacturing Industry

The rise of automation in liquid packaging is expected to trigger significant changes in the food manufacturing industry. This shift will influence diverse aspects from quality assurance and cost management to production volume. By transforming traditional practices, automation holds the potential to redefine industry standards and usher in a new era of efficiency and innovation.

- Quality Assurance: By reducing human error and offering precise control over packaging processes, automation will enhance product quality and consistency, building consumer trust and loyalty.

- Cost Management: Initial investment in automation may be high, but in the long run, it significantly reduces labor costs, material waste, and downtime due to equipment failures, translating into substantial savings.

- Increased Production Volume: With higher efficiency and speed, automated packaging lines can meet the growing demand for food products, especially in rapidly urbanizing regions.

Overcoming Challenges in the Adoption of Automation

Embracing automation in liquid packaging brings numerous benefits, but the path to full adoption is challenging. Several challenges need to be proactively addressed to unlock the full potential of automation and chart a successful course for the future. These include:

- Skill Gap: The transition to automated technology requires workers to acquire new skills. Investment in training and education will be key to successfully harnessing the benefits of automation.

- Data Security: As automation depends heavily on digital data, protecting this information from potential cyber threats will be crucial.

- Adapting to Regulatory Changes: With the incorporation of automation, new regulations may arise. Businesses will need to stay ahead of these changes to remain compliant.

Embracing the Future of Liquid Packaging

The future of liquid packaging in the food manufacturing industry will be molded by automation. It’s a catalyst for transformation that stands at the crossroads of innovation, efficiency, and sustainability. Through automation, manufacturers can quickly meet evolving consumer demands, maintain competitiveness in a dynamic market, and contribute positively to environmental sustainability. It also creates new opportunities for introducing innovative packaging designs and materials, stimulating creativity in packaging solutions.

As we look toward the future of liquid packaging, the influence of automation cannot be overstated. With its ability to increase efficiency, enhance accuracy, improve worker safety, and foster sustainability, automation represents a fundamental shift in the industry’s landscape. Challenges in adoption exist, but with adequate preparation, training, and regulatory adherence, these can be solved. Ultimately, automation will help to redefine standards in the food manufacturing industry.