Labor shortages in global manufacturing are threatening to jeopardize growth within the industry.

Ageing workforces and the changing expectations of the next generations of workers are leaving jobs unfilled and firms in search of a long-term answer. Recruitment challenges and an ever-widening skills gap need to be rapidly addressed, and automation could provide an effective solution.

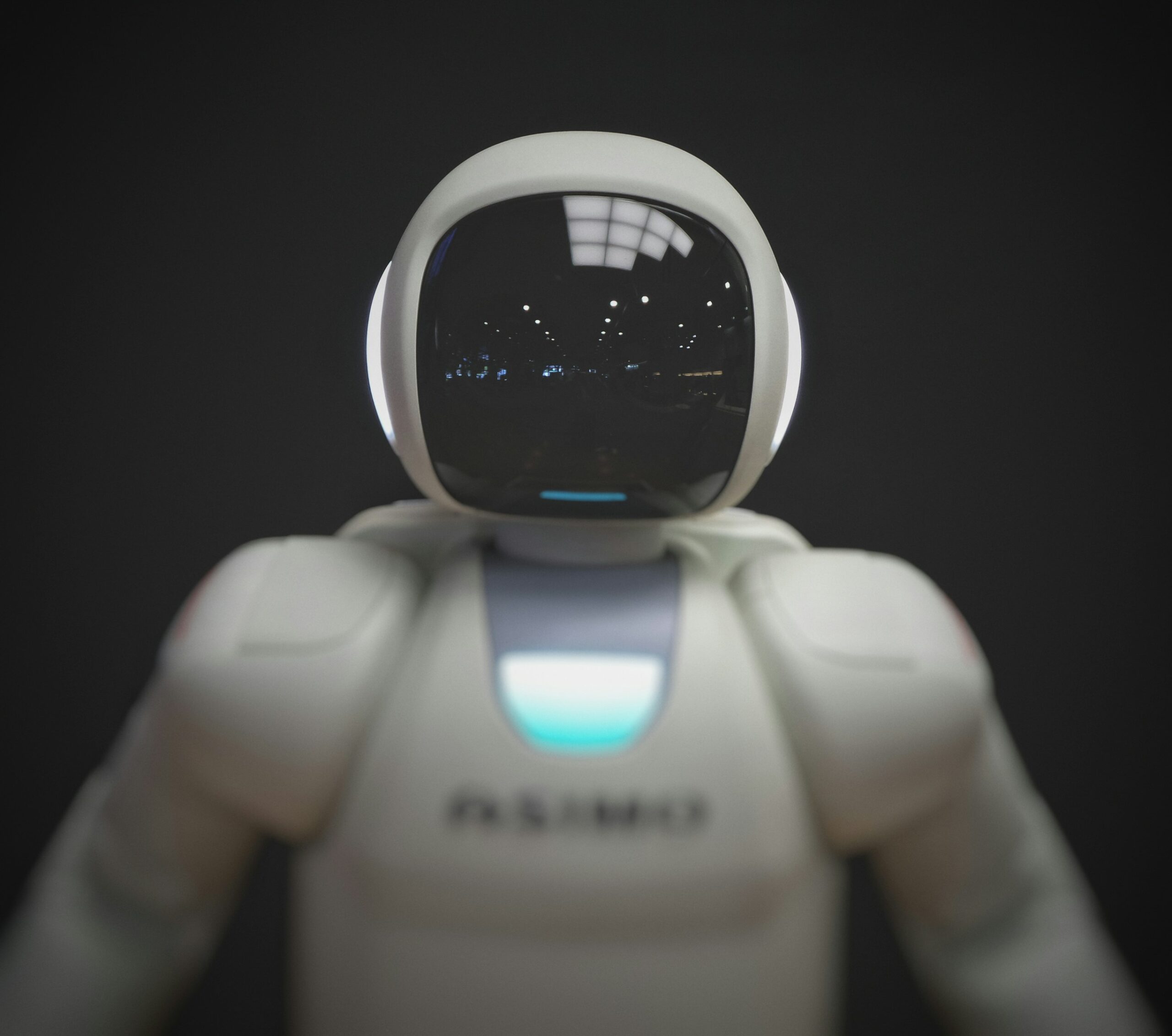

Manufacturers can use robotics and artificial intelligence to carry out a range of tasks but they also need to attract people with the skills to program and operate these new technologies.

Collaboration between the human workforce and robots offers manufacturing firms the opportunity to speed up production, improve safety, and attract talent they desperately need.

How could automation solve labor woes?

Robotics can be widely used in manufacturing to complete repetitive tasks quickly, helping to increase production. Many manufacturing departments – including assembly, raw material handling, product packaging, and shipping – can take advantage of technological advances.

Although it means a substantial investment for manufacturing firms, automation can reduce their costs in the long term. Ultimately, the investment creates a ‘smarter’ workplace that’s more streamlined and efficient.

Furthermore, recruitment is a significant task for employers and a high turnover of staff and regular recruitment campaigns create a financial drain on businesses.

Automation in the manufacturing industry

Augmented reality (AR) and virtual reality (VR) are just two innovations that can address the skills shortage within the industry.

Building a ‘digital twin,’ which is a digital representation of a physical asset, allows a company to access meaningful data and better understand its production processes.

‘Industry 4.0’ is the term used to describe the move towards greater automation in manufacturing and the best use of big data that’s generated as a result. Firms struggling to hire maintenance engineers, for example, can use artificial intelligence to predict when a machine might fail and implement protocols that preserve its useful life.

Benefits of automation as a labor solution

Improved safety

Manufacturing can be a dangerous industry given the heavy machinery and equipment required to produce at volume and speed. Robots can be assigned to areas where health and safety are an issue. Repetitive strain injuries can also be avoided by using machinery to carry out monotonous processes.

Increased production

Unlike humans, robots don’t require regular breaks so their speed and consistency of operation can quickly increase production. This, in turn, leads to improved profitability and growth for manufacturing firms as they become more competitive in their market.

Consistent higher-quality products

The risk of human error in the industry makes the precise programming of robots an attractive proposition that leads to fewer mistakes and consistently higher-quality output. The competitive nature of manufacturing, time-sensitive issues around production and delivery, and health and safety concerns can be effectively addressed by automation.

A permanent solution to labor shortages

Rather than taking jobs from humans, automation offers companies the opportunity to attract talent with the right skills and assign those skills to the most appropriate areas of the business. That places the human workforce in an environment that promotes growth, putting their skills to best use.

Editor’s note: Jon Munnery is an insolvency and company restructuring expert at UK Liquidators, a provider of company liquidation services.