To thrive in today’s highly competitive market, food and beverage businesses need to understand exactly where they make money—and where they don’t. While that might sound obvious, for many businesses pinpointing which products, services, and customers are profitable or identifying operational changes to improve profitability is anything but clear.

Whether it’s a startup with an unsophisticated operation or a billion-dollar sophisticated global food and beverage enterprise, accurate cost and margin information is critical to cash flow, profitability, and competitiveness. Often, companies believe they’re using correct cost data to make decisions but end up disappointed by the results.

Common Signs of Cost and Margin Intelligence

Consider a food and beverage company that’s experiencing significant growth in production volumes and net revenue. Yet, margins are lower than expected, or even shrinking. Executives are surprised by the poor results, and the chief financial officer can’t explain why. The executives are asking, “With good customers and contracts, why are margins shrinking?” The answer may be that new contract pricing was based on incorrect costs because the management team did not fully understand their cost drivers. Here are some examples:

- Overhead costs are spread like “peanut butter,” incorrectly burdening low-complexity SKUs and unknowingly favoring others.

- Due to product lead times, some materials need to be stored in the freezer for an extensive period, taking up space from higher moving items. These extra costs are included in the “peanut butter.”

- Sales commits to ship directly to remote stores to secure a retailer’s business and doesn’t factor in LTL freight to the cost/price.

- The product is produced on an expensive and highly automated line, but overhead is applied using labor time, causing SKUs produced on this line to be under-costed.

- Direct labor benefits and taxes are included in overhead, which is treated as “peanut butter” in an average-cost-per-unit for the plant. SKUs with packaging requiring 10 operators receive the same overhead cost as those with two.

In the examples above, CFOs lack the data or the experience to properly assign costs. They don’t understand the company’s cost structure and therefore lose visibility into where they’re making and losing money.

Root Causes of Low or Shrinking Food & Beverage Margins

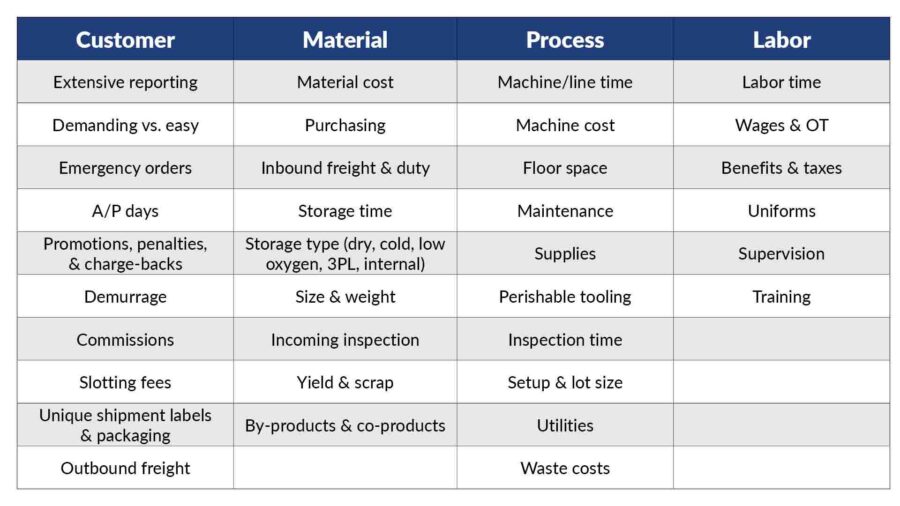

Many growing companies fight for shelf space with major retailers and these contracts are critical to cash flow, brand visibility, and success. When revenue rises but margins unexpectedly shrink as the business fulfills customer orders, it often means the company isn’t accounting for all the costs necessary to serve the retail customer. To understand true margin (not just gross margin), food and beverage companies need to incorporate all the costs to serve—customer, material, process, and labor costs—into their costing models. Take a look at this diagram of key cost drivers:

Greater Insight Enables Control and Visibility

Don’t let inaccurate costs eat into your margins. An informed approach to costing gives all companies control when negotiating customer pricing. It helps them understand how low (or high) they can quote a strategic opportunity. It enables them to proactively manage margins and on a real-time basis determine price increases. Understanding the entire cost to serve each customer is especially important during periods of volatility, uncertainty, and high inflation. Knowing true costs and margins enables strategic and operational decision-making that improves the bottom line and competitiveness in today’s marketplace.

Author’s contact info:

About Plante Moran

Plante Moran is among the nation’s largest audit, tax, consulting, and wealth management firms and provides a full line of services to organizations in the following industries: manufacturing and distribution, financial services, service, healthcare, private equity, public sector, real estate, construction, and energy. Plante Moran has a staff of more than 3500 professionals throughout the United States with international offices in Shanghai, China; Mumbai, India; Tokyo, Japan; and Monterrey, Mexico. Plante Moran has been recognized by a number of organizations, including Fortune magazine, as one of the country’s best places to work. For more information, visit plantemoran.com.