Walmart is tapping automation to help its store fleet handle last-mile grocery delivery, adding local fulfillment centers (LFCs) that will turn parts of them into mini warehouses and speed up fulfillment for local customers. The retailer is partnering with third-party technology providers including Alert Innovation, Dematic and Fabric to fuel innovation on this front.

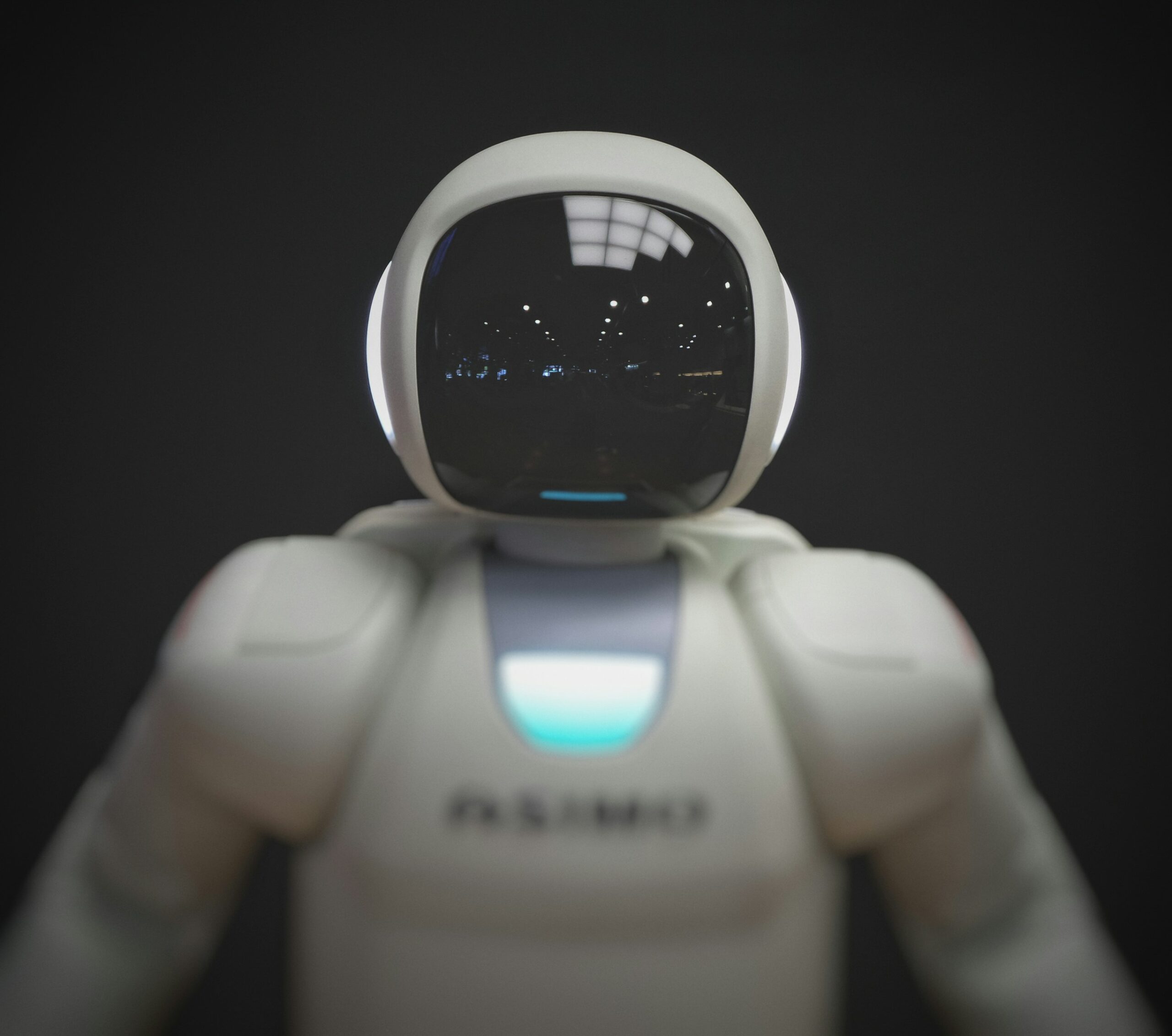

LFCs will utilize robots rather than associates to pick most orders. Each LFC can store thousands of items based on what nearby customers order most frequently, from consumables to electronics. However, the human touch will remain: personal shoppers handpick fresh items like produce, meat and seafood to ensure quality.

Once the order is collected, the LFC system stores it until it’s ready for pickup. This whole process can be completed in a matter of minutes from the time the order is placed to the time it’s ready for a shopper or delivery driver to collect.

This effort is partially in response to the pandemic, during which Walmart’s online fulfillment growth— including both pickup and delivery – peaked at 300%, according to CNBC. The number of new customers using the services quadrupled in the early days of the lockdown, which led to Walmart boosting slot capacity by 40%.

“These local fulfillment centers help unlock our ability to expand even faster to meet [customers’] needs today,” said Tom Ward, SVP of Customer Product, Walmart U.S. in a blog post.

KROGER EXPERIMENTS WITH HIGH-TECH CARTS

Kroger has partnered with solution provider Caper to launch KroGo shopping carts at a Cincinnati location, which are capable of handling checkout automatically, according to Forbes.

The KroGo carts are being advertised as offering a faster checkout experience while limiting contact with store associates amid the pandemic. Additionally, shoppers are encouraged to use the carts with a 5% discount on Kroger-branded items, further boosting adoption and giving customers a reason to check out higher-margin private label items.

Caper claims that its tech-enabled shopping carts are more affordable and easier to deploy than rival automated checkout systems such as AmazonGo and Standard Cognition. These technologies leverage cameras and other sensors to detect when items are removed from shelves, rather than putting the focus on the shopping carts themselves.

Caper says it is working on pilot projects with six other major U.S. supermarket chains and counts Canada-based Sobey’s as one of its first customers. The Kroger pilot could also expand to more of the company’s 2,750 stores in the future.

ROBOTS POWERING NEXT-GENERATION CLEANLINESS

Spill-detecting robots have been in stores for several years, but now the newest generation of cleanliness-focused automation is using UV rays. Retail Business Services (RBS), the services company of Ahold Delhaize USA, has partnered with Ava Robotics to launch an automated cleaning solution at two distribution centers, while Badger Technologies has introduced its own disinfecting robot.

Ava Robotics’ solution has applications to disinfect both air and surfaces at a rate of about 9,000 square feet per hour, with 99% effectiveness against COVID-19. The robots are fully autonomous and offer facility managers remote access and emailed reporting to ensure they are handling the necessary tasks on their own. The machines use screens and speakers for disinfection-related announcements to ensure they can work alongside any humans in the area.

The Badger UV Disinfect robots can decontaminate 40,000 square feet in about two hours and are designed to work in and around typical store spaces such as shelves, aisles and checkout areas.