DUBAI, United Arab Emirates – An international event celebrating innovations in manufacturing achievements in the Middle East and abroad, Gulfood Manufacturing celebrated its first decade influencing the world of food and beverage manufacturing on November 5-7.

The event united more than 2,500 food manufacturing leaders and an additional 45,000 visitors to observe rapid developments in the industry. Some of the progress charted includes the steady shift to Industry 5.0, an approach that focuses developments on social value and human prosperity rather than purely economic gains, and technological advancements improving processes across the supply chain.

Let’s dive into some of the key takeaways from the event:

The Sustainability Standard

Implicit in many Show floor booth conversations and education session discussions was the call for companies to hit their greenhouse gas emissions reduction targets and promote a more environmentally friendly future.

In a session about imagining a smarter, more sustainable food industry, prominent CEOs discussed the need for F&B to protect the environment as the global supply chain strains to support the world.

“We want to feed a growing population, so we will have to do it in a sustainable way,” explained Alvaro Martinez, CEO of WEMEA and LAM, at GEA Group. However, to bring the prerogative to the masses, these solutions must be accessible.

“It’s all about making sustainability affordable and not only catering to a niche. Sustainability needs to be economically [viable],” added Samuel Sigrist, CEO of SIG. His company was one of those identified by Gulfood Manufacturing for its strides to herald a more environmentally conscious future.

The recent industry push is also coming from global government initiatives in the UAE and in the EU that focus on traceability and conservation. In a conversation with The Food Institute, Marcelo Piva from Tetra Pak stressed the importance of government programs to promote a better world.

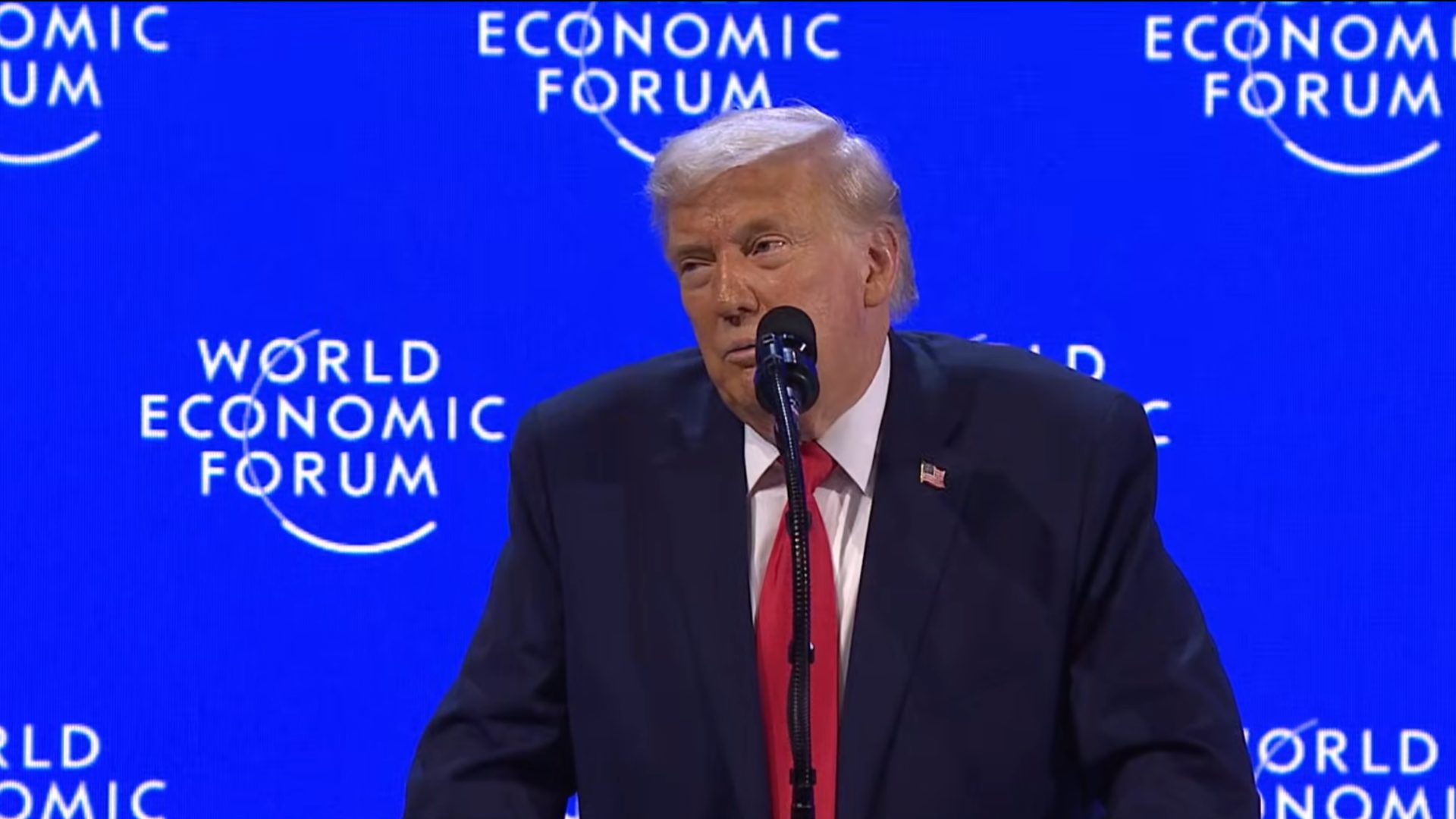

What companies and consumers do for sustainability is great, but major change will not occur until governments get involved, he said. In a later education session, World Economic Forum carbon and blockchain expert Erin Grover agreed while adding nuance to the issue. She indicated that, although these changes are necessary, programs must not leave out a key, often overlooked aspect of the supply chain – smallholder farmers who may lack the technology or infrastructure to abide by the government regulations.

Plant-based companies and those that advocate for alternative protein sources also made an impact at the event, with many noting that the United Nations’ projection of nearly 10 billion people by 2050 means that countries will have no choice but to invest in plant-based protein or lab-grown meats because the planet lacks the space, explained Anthea Ayache, founder of the magazine The Ethicalist.

Alternative proteins represented at the show included Mush&’s mycelium fungi protein product, as well as plant-based solutions such as Tetra Pak’s flavorings and flagship fava bean ice cream, Kerry Group’s various meat and dairy alternative lines, and IFFCO’s clean label plant-based meats launched under its recent initiative called Thryve. The lattermost company boasts the first 100% plant-based manufacturing facility in the Middle East.

Tech-Enabled Ingredient Discovery

CPG brands, flavor houses, and data insights firms alike rejoiced in the capabilities of AI, blockchain, and Internet of Things (IoT) with its latest innovations in technology.

Flavoring firm Givaudan showcased a machine for its manufacturing clients that allowed the user to adjust quantities of scents in real-time through a mask attached to the device. Additionally, DSM-Firmenich showcased an AI-enabled precision fermentation technology that allows users to customize the taste and texture profiles of different proteins for animal-free yogurt producers.

Symrise also wowed with a recent program that allowed them to create AI chatbots that emulate specific consumer types. For example, users can interact with Symvision AI’s archetypes to determine whether a New York-native Gen Z consumer or a Gen X shopper living in Dubai would be receptive to a specific offering.

“We know that products only work today when they appeal to certain need states,” explained Dr. Dariah Vanessa Lutsch, global sensory and consumer insights research director at Symrise AG. With the chatbots “we can get a first indication as to whether a flavor will work, speeding up the go-to-market [strategy].”

Smarter Supply Chains

Flavors companies weren’t the only brands to get the tech treatment – manufacturing equipment also benefited greatly from recent developments to offer supply chain solutions that increased security and resilience while also advocating for sustainability and efficiency.

Justin Steinbach, CEO of IFFCO, explained how the company’s unflappable commitment to hitting its aggressive sustainability targets. One initiative touted supply chain efficiency that uplifted the environment and the company. In partnership with a firm in Sharjah, UAE, the company’s production facility reclaims oil waste from its manufacturing operations and turns it into biodiesel to fuel its delivery trucks.

Technologies across the supply chain are also allowing companies to ensure safer supply chains through smart monitoring tactics. In a conversation about building resilient food supply systems, Manu Bhalla of Freight Systems Group noted how temp controllers leveraging IoT can constantly monitor the temperatures for food being transported or stored and notify teams if issues are found, ensuring food doesn’t spoil.

Additionally, he added that recent AI technologies have been able to make warehouses more efficient by suggesting organization strategies that can optimize for aspects like expiration dates or seasonality.

Athar Siddiqui, EVP at Siemens, took AI a step further by explaining that recent technologies have allowed facilities to create “digital twins” of every machine to better predict if or when they will break down. This knowledge then allows these stakeholders to determine the best time to make repairs to the product. The benefits of these programs are multifold, including minimizing machine operation downtime and decreasing the risk of food wastage from defective machinery.

However, as factories become more tech-enabled Tony Meghabghab, managing partner of QSpeed Robotics, noted that these technologies cannot exist in a vacuum, and even as companies accelerate their implementation of AI solutions, humans will always have a place in the supply chain.

“A factory that has smart manufacturing would be more efficient, sustainable, and cheap, then it enables the factory to grow,” he said. “[But] humans will still be at the center of everything. Everything that we do around innovation today is around humans. If it is not, then it has lost its purpose.”