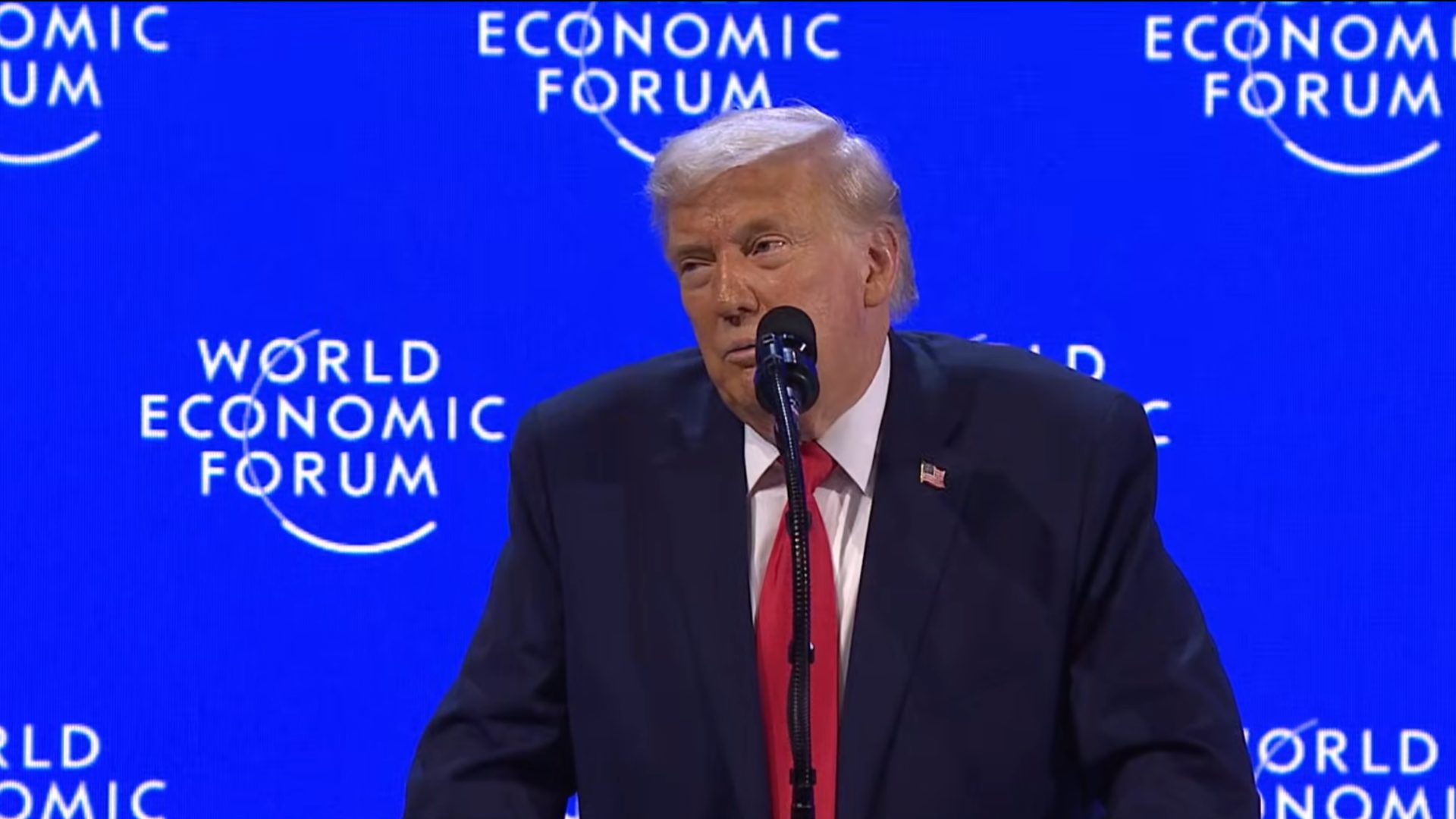

Food and beverage businesses have begun to feel the impact of tariffs imposed by President Donald Trump. Some have absorbed the blow. Others were left staggering.

When the U.S. raised steel and aluminum tariffs to 50%, for instance, the impact was felt far and wide.

“Coca-Cola avoided higher metal costs by switching more of its drinks from cans to plastic bottles and using less metal where it still needed to,” Bernard Meyer, an e-commerce expert at Omnisend, told The Food Institute. “On the other hand, Campbell’s and Hormel – which depend on canned packaging – were hit hard; tin prices rose, and they had no quick way to avoid the cost.”

Recent tariffs on ingredients and packaging from China, Canada, Mexico, and the European Union have added more pressure felt throughout much of the F&B industry.

The ripple effects of the tariffs are impossible to ignore.

“If you’re bringing in ingredients or products from overseas, you’re already feeling it in your margins,” said Joe Camberato, CEO of NationalBusinessCapital.com.

Nearly 60% of business leaders say their operations have already been significantly affected by new tariffs imposed by the Trump administration or by U.S. trade partners responding to those measures. The survey, conducted by Endeavor Business Intelligence, also revealed that more than a third of business leaders say their operating costs have jumped by at least 10%.

When packaging becomes more expensive, food producers understandably raise prices. Retailers pass those increases to shoppers, demand typically drops, and farmers cut back on what they grow. Additionally, importers rush to bring in goods before new tariffs start, which often overloads ports one month while slowing shipping the next.

Meanwhile, inventory planners struggle to keep up with the swings.

“Tariffs cause immediate cost increases at the sourcing level, quickly cascading through manufacturing, distribution, and retail channels,” said Jake Hyten, CEO of Superior Supplement Manufacturing. “Ultimately, consumers experience higher prices and reduced product availability. Additionally, uncertainty creates inefficiencies, prompting businesses to hold larger inventories, impacting cash flow.”

Tariff Trouble Ahead

Levies appear poised to impact nearly every industry player in the coming weeks.

“These ripple effects often compound across the supply chain. For example, an upstream change in ingredient sourcing might trigger manufacturing delays, which disrupt distribution times and lead to retail out-of-stocks,” noted Tarun Chandrasekhar, chief product officer at Syndigo.

“In a market with high consumer expectations around availability and pricing, these cascading impacts can damage margins and brand trust.”

The current trade war reminds some industry experts of the tensions between the U.S. and China in 2018-19. Some say it’s the most intense trade dispute since the 1930s.

So, how can businesses go about dodging significant blows brought on by trade unrest?

“You’ve got to stay ahead of it,” Camberato said. “Know your numbers, watch your margins, and be ready to adjust your pricing.

“You can’t eat every increase and expect to stay afloat – especially in the food business, where margins are already tight.”

10 Secrets to Surviving Trade Uncertainty

Industry experts offer countless solutions for navigating challenges brought on by tariffs. Here are their most common suggestions:

- Diversify your supplier base

- Build relationships with alternative suppliers

- Secure multiple supply routes

- When possible, source locally

- Narrow assortments to manage margin risk

- Utilize free-trade zones to defer duties

- Explore alternative materials for packaging

- Utilize analytical tools

- Lean into AI and predictive technology

- Build a strong data foundation that keeps all parties informed

Simply put, 2025 is a time to get creative as an F&B business leader.

“There’s a science behind how items are classified for imports to avoid tariffs,” said Amrita Bhasin, CEO of Sotira. “I predict that companies will look at substitute materials or a hybrid of materials so they can claim their imports as a different category that has lower tariffs.”

Most industry experts expect tariff-related uncertainty to stretch into next year.

“Unless major trade policy changes happen soon, tariffs are likely to continue through 2026,” Meyer said. “Some increases are already planned, and there’s no sign of faster trade deals.”

“For now,” he added, “companies are adjusting by building flexibility into their contracts and supply networks, knowing this uncertainty isn’t going away quickly.”

Of course, supply chains haven’t been static in the food and beverage industry in decades.

“What’s different now is the back-and-forth political theater of it all. Tariffs come and go like weather fronts,” said Frank Kenney, director of industry solutions at Cleo. “And businesses are left to answer questions that shift by the quarter: Will a 60% tariff on Chinese goods stick? Will imports from Mexico remain viable?”

Tariffs often result in fear and uncertainty regarding the impact of prices. No one wants to be remembered as the brand that raised prices and frustrated customers, Kenney noted.

When volatility hits from tariffs, the real cost isn’t a late shipment. It’s an irritated shopper, a rattled boardroom, and a bumpy road to regain public and investor trust. Because of that, companies must strategize – and act fast.

“The companies that thrive in this environment are the ones using [their] capabilities to fuel something bigger – a strategy that not only keeps them operational, but actually uplifts the business when the heat is on,” Kenney said.

The Food Institute Podcast

Several economic headwinds indicate the consumer is being financially stretched, but we all need to eat – so what are consumers actually buying at the grocery store? Nik Modi of RBC returns to The Food Institute Podcast to discuss channel differentiation, consumer product selection, and other macro trends.