According to the Green Climate Fund, around 30% of food produced for human use is wasted or lost along the supply chain annually. That statistic represents a significant challenge for the food and beverage supply chain.

This challenge can lead to increased costs, stock shortages, and weakened consumer trust. To overcome this issue, you may be forced to hold excessive inventory as a bulwark against the uncertainties along the food supply chain. Unfortunately, holding stock comes with risks and additional costs.

Here’s a look at how to navigate food supply-chain challenges in 2025:

Build Resilience to Prevent Supply Disruptions

It’s essential for players in the F&B industry to build resilience in the supply chain to ensure a steady flow of food products. This involves anticipating potential disruptions and implementing systems that can absorb and adapt to these challenges. Some of the ways to build resilience include:

Choosing a Reliable Carrier

In the F&B world, choosing a logistics services provider offering temperature-controlled shipping is essential to prevent spoilage of supplies in transit. Delays in delivery and a lack of proper handling of refrigerated and/or frozen products can negatively impact the freshness and safety of your products – leading to significant losses. Speedy delivery ensures that companies can not only fulfill every order, but helps to ensure the freshness of the product.

Risk Assessment

Frequent risk assessments can help pinpoint vulnerabilities, enabling timely interventions and maintaining supply chain stability. By using data analytics and other supply-chain management tools, companies can better understand their supply chain dynamics and respond swiftly to threats.

Creating End-to-End Visibility

Food distributors and manufacturers can integrate tracking systems into their existing inventory management software to enhance the visibility of their supplies. For example, if you already have an ERP, you can integrate it with a Transportation Management System (TMS). Through a TMS, you get real-time data concerning the status of your shipment, location, and expected arrival time.

Integrating IoT technologies such as RFID can help keep track of incoming and outgoing inventory as well as the location of products within a distribution center. This way, you can maintain optimum stock levels.

Leveraging Real-Time Tracking for Demand Transparency

Real-time tracking helps provide detailed insights into the location and condition of products and goods throughout the supply chain. Here’s how food companies can leverage real-time tracking to ensure freshness of supplies:

Reducing Food Waste

Globally, one-third of all food produced for human consumption is lost or wasted, equating to one billion meals daily.

Real-time tracking systems ensure products are delivered in optimal condition, minimizing food waste. This technology also empowers food distributors, retailers, and consumers with freshness data, encouraging timely consumption and reducing household waste. The approach leads to cost savings. Less waste translates to reduced loss and more efficient resource use.

Improving Supply Chain Efficiency

Real-time tracking streamlines supply chain processes, from monitoring product conditions to optimizing logistics. This technological integration reduces manual errors and supports swift decision-making. Through automating routine tasks and providing actionable insights, companies can reduce bottlenecks and streamline workflows. The outcome is a more agile supply chain.

Sustainable Logistics: Meeting Demands in 2025

The UN’s Sustainable Development Goals aim to halve global food waste by 2030. ESG considerations are imperative for food producers that intend to catch up with the evolving regulatory pressures and consumer expectations. Strategies to meet consumer and ESG demands through sustainable logistics include:

Measuring Scope Emissions

If your aim is to reduce your Scope 3 transportation-related greenhouse gas emissions, you must be able to measure your current emissions. A Logistics Services Provider can leverage integration technology to capture and measure your Scope 3 emissions by mode and location, to help you better understand where to apply your decarbonization efforts for greatest effect.

Adoption of Eco-Friendly Packaging and Shipping Practices

Distributors and retailers must embrace eco-friendly packaging and optimized distribution routes to meet consumer demands for sustainability. This shift not only reduces carbon footprints but also enhances brand reputation. By prioritizing sustainability, companies equally comply with regulatory requirements and gain a competitive edge.

Integrating Renewable Energy Solutions

Implementing renewable energy in logistics operations, such as solar-powered warehouses and electric vehicles, can reduce environmental impact and operational costs. These innovations lower emissions and reduce dependency on non-renewable resources. Investing in renewable energy also improves resilience against energy price volatility.

Engaging in Circular Economy Practices

Adopting recycling and reuse strategies helps minimize waste and encourages optimum resource utilization. By sealing the loop, companies can create value from waste, turning it into a resource for new products. This strategy reduces the requirement for virgin materials and cuts production costs.

Optimizing Supply Chains with Automation and AI

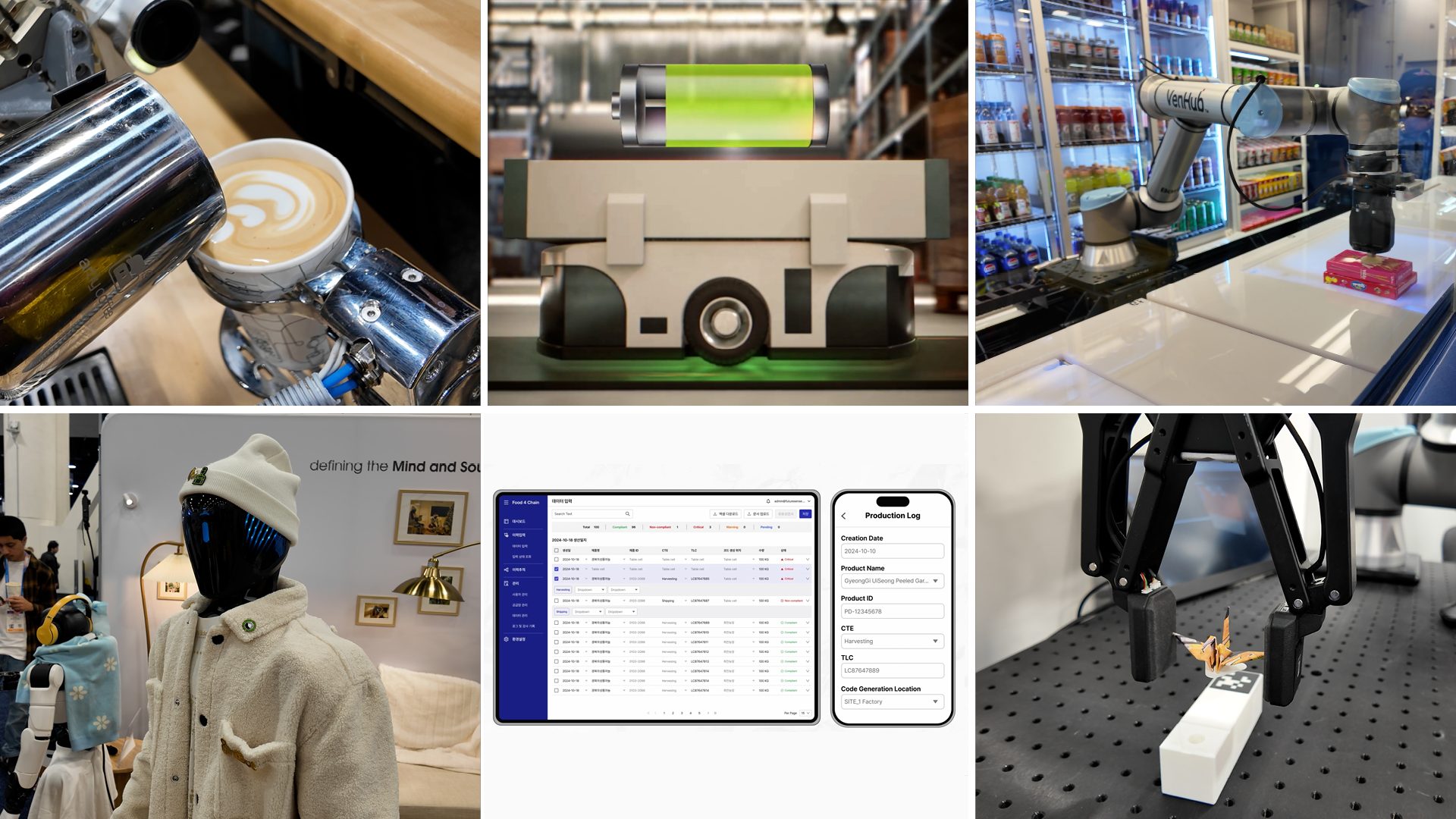

Smart supply chain management is the future of logistics. With the help of automation and artificial intelligence (AI), companies can optimize their operations, reduce costs, and enhance efficiency. According to Ethan Soloviev, AI will impact 90% of the food we consume by driving efficiencies in the global food supply chain. Some of the ways automation and AI are transforming the supply chain include:

Predictive Analytics for Demand Forecasting

Predictive analytics allows food companies to forecast demand accurately, reducing excessive inventory or stockouts. By analyzing market trends and historical data, companies can anticipate shifts in consumer preferences and prepare accordingly.

Automated Warehouse Management

Companies can utilize AI and analytics to automate warehouse processes to increase efficiency, reduce errors, and optimize space utilization. Automation typically leads to cost savings and improved operations. Robotics, RFID, and barcode technologies can streamline picking, packing, and sorting, freeing human resources for more strategic tasks.

Autonomous Vehicles for Delivery

Leveraging autonomous vehicles for last-mile delivery ensures timely delivery of products without human intervention. These vehicles can operate around the clock, improving delivery speed and reliability.

Strengthen Your Supply Chain

In light of growing food supply-chain challenges and demand for sustainable business practices, industry leaders must enhance their supply chains. By implementing resilience-building, real-time tracking, sustainable logistics, plus AI-driven automation, your organization will be a leader in a rapidly evolving industry in 2025 and beyond.

About the author: Nick Fryer has over a decade of experience in the logistics industry, spanning marketing, public relations, sales enablement, M&A and more at 3PLs and 4PLs including AFN Logistics, GlobalTranz, and Sheer Logistics.

The Food Institute Podcast

Is it possible to balance a legacy brand and innovative ideas for a food company? Bibie Wu, chief communications and technical development officer with Del Monte, shares how her company respects its past while looking to the future, and how her dual roles in marketing and product development inform each other and improve the company.