Research and development divisions at food companies report shortages of ingredients like MSG, sweeteners and soluble fiber are handicapping product development.

Additionally, predictions indicate the problem could last well into the next decade.

The 2022 R&D survey from Food Processing indicated though product development work is approaching pre-pandemic levels, shortages of ingredients, short-staffing and work-from-home strategies were slowing the work.

Food Processing queried 152 product developers many of whom said they were reducing their offerings, with nearly half of those queried saying they were having trouble sourcing ingredients.

The ingredient supply has gotten tight across the board and is expected to get even tighter, an Ohio R&D manager told the publication. Another respondent said it wasn’t unusual to tap second- and third-tier sources.

“Unfortunately, this is a really hard area to address. A company can look for other venders for items but the concern is always the quality of product and safety of replacing your trusted supplies,” Trevor Craig, technical director for food testing at Microbac Laboratories, told The Food Institute. “Another option some companies look for is a replacement of certain materials where possible with a similar product, but it really depends on the product and what they’re looking for.”

ABSENT INGREDIENTS

Among the ingredients in short supply are: MSG, preservatives, artificial sweeteners, starches & gums, maltodextrin and soluble fiber, as well as fats and oils, whose prices have skyrocketed.

Popular Mechanics reported (June 16) ingredient shortages include the following, as well: sriracha hot sauce

- potatoes

- cream cheese

- champagne

- maple syrup

Problems were exacerbated by supply chain issues that developed because of pandemic shutdowns and subsequent tie-ups at ports, plus a shortage of shipping containers and warehouse space.

Smoothie King told The Food Institute it was able to avert the worst of possible supply chain issues with robust analytics and prioritizing plans that were developed well in advance of the pandemic.

POSSIBLE SOLUTIONS

“Smoothie King was able to offer their entire menu from pandemic to present by strategically pivoting to using multiple countries of origin and suppliers for tropical fruits to avoid ingredient shortage. These relationships helped them lean into available reserves such as available freezer space, freight, and more, spreading excess items across the country near locations that were soon to experience a supply chain shortage,” said Barbara Mayrand, Smoothie King vice president of supply chain.

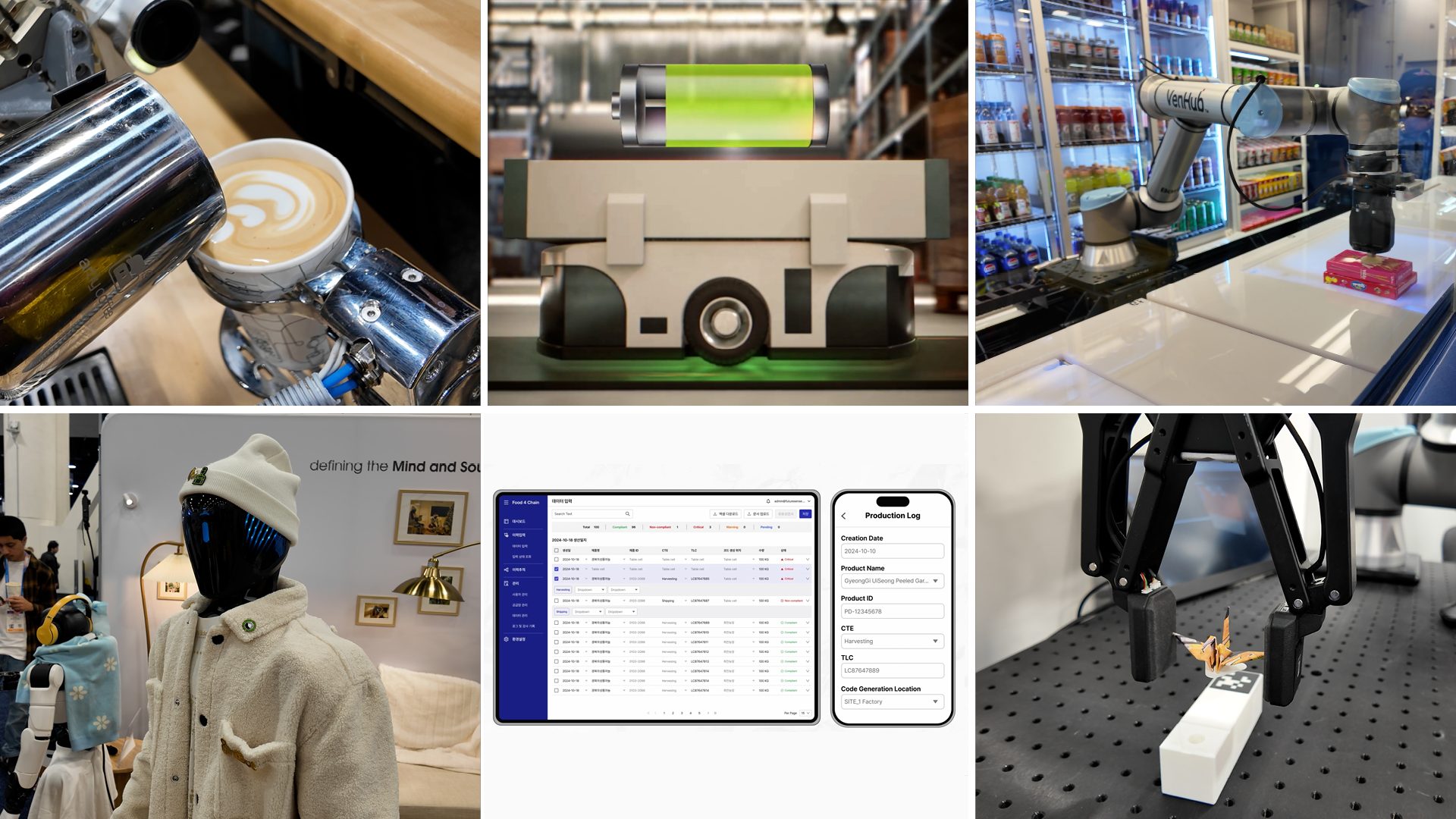

Kingdom Supercultures said mass scale food production soon could take on a new look. Artificial intelligence is being used to develop microbial cultures that can mimic the chemical ones used today, combatting ingredient shortages and making plant-based options more affordable for CPG brands.

But though interest in plant-based products has grown in recent years, at least one survey respondent said expectations are that consumers gradually will return to pre-pandemic behaviors, leading to a slowdown in the alternative meat and milk sectors.