The impact of AI on supply chains is immeasurable. For starters, food and beverage companies are seeing strong results from predictive maintenance systems powered by machine learning.

“For manufacturers, that’s not a nice-to-have – it’s operational insurance,” said Dag Calafell, director of technology innovation at MCA Connect. “Every minute a machine is down means money lost – and if your factory can’t warn you before it fails, it already has.”

In 2025, machine learning and automation solutions have inspired companies to rethink standard operating procedures. Computer vision catches quality defects at line speeds. Vision systems detect contamination, packaging errors, and label mistakes … and the list goes on.

“Industry research shows consistent results. Food manufacturers using AI quality control report fifteen to thirty percent better defect detection,” Daryl Edwards, the founder of Agent Impact, told The Food Institute. “Plants with predictive maintenance reduce unplanned downtime by twenty to forty percent. The pattern repeats everywhere.”

For companies that know how to use it, AI is already a game-changer.

“We’re moving to autonomous supply chain AI agents that manage orders, coordinate logistics, and optimize inventory. That’s not science fiction,” said Wyatt Mayham, of Northwest AI Consulting.

Yet, for many smaller and medium-sized businesses, AI still feels out of reach. After all, if a system makes a high-stakes recommendation but can’t explain its reasoning, it’s hard for managers to trust it. As Mayham noted, there’s also vendor overload these days, with a flood of AI-related startups promising a huge ROI; sorting out what’s real versus what’s hype requires valuable time that most operators simply don’t have.

So, while the potential of AI appears boundless, adoption of the technology remains uneven.

The Best Use Cases for AI

Instead of relying on handheld computers, retailers and food logistics companies are using smart data capture software on a mix of mobile devices, wearables, robots, fixed cameras, and drones to transform workflows across the supply chain.

“These systems go far beyond just reading barcodes,” noted Jessica Grisolia, director of retail solutions at Scandit. “Leveraging machine learning and AI, they interpret context, detect the intended target among multiple codes, work in difficult conditions like low light, and offer tailored user guidance via augmented reality overlays.”

Experts say AI can be especially impactful on the following elements of business:

Forecasting. The best predictive models aren’t just relying on past sales, they’re pulling in real-world variables like weather, promotions, and even local events, Mayham said. By considering those factors, businesses are benefiting from tighter inventory planning and less spoilage.

Warehouse automation. “We’re seeing warehouse management systems that do more than track bins,” Mayham said. “These tools now optimize inventory placement based on real-time demand signals, and coordinate with autonomous mobile robots to handle picking and packing. Everything moves faster, with fewer errors.”

Routing. AI is now being used to reroute deliveries on the fly. These systems respond to real-time traffic, along with last-minute order changes to optimize across fuel, timing, and driver hours all at once.

Quality control. Computer vision is being used on production lines to catch defects with over 99% accuracy, Mayham said. That improves both safety and consistency without slowing down a line.

AI in Action

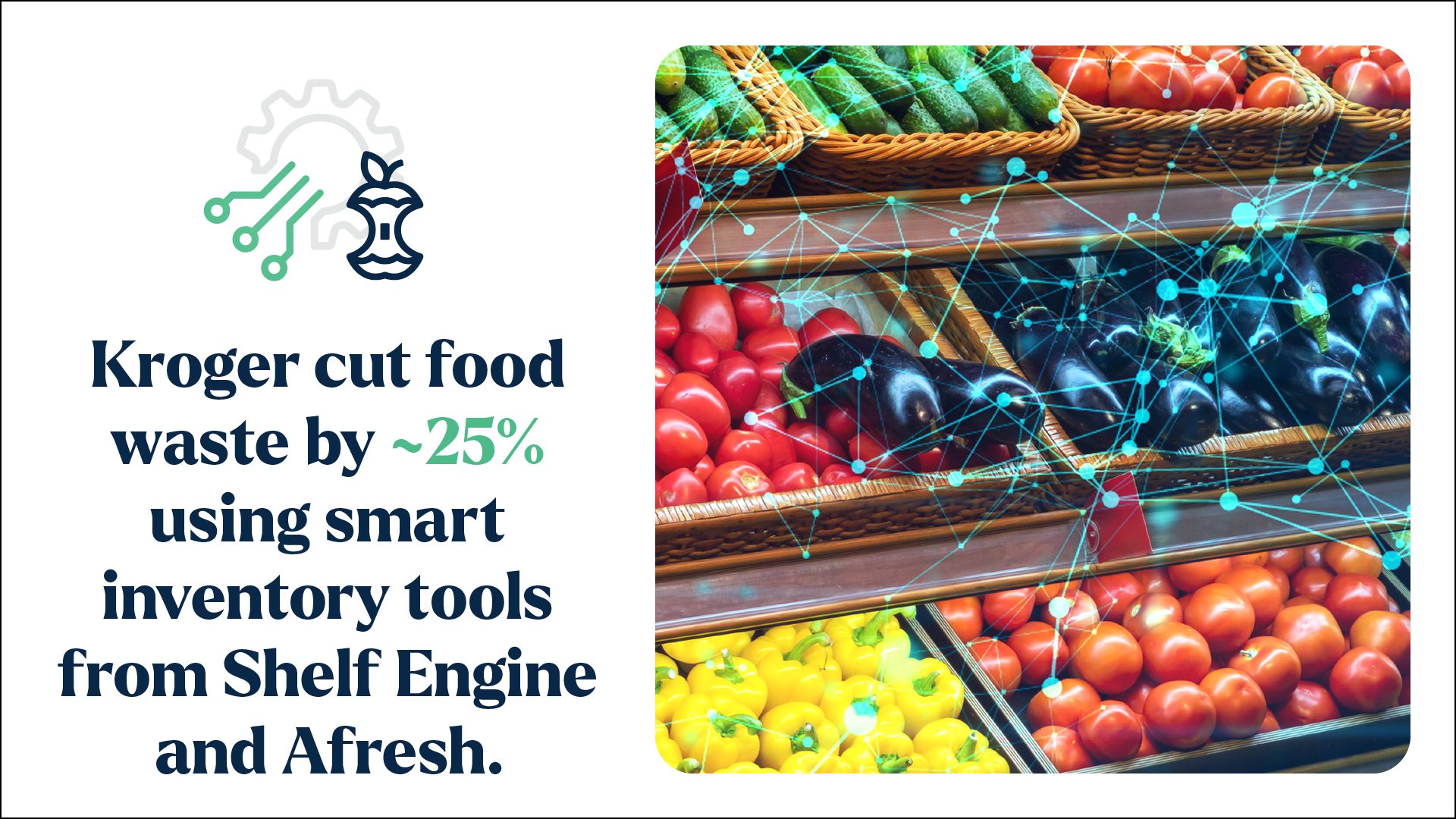

Grocery giant Kroger has adopted tools from Shelf Engine and Afresh to manage fresh inventory, and has seen a roughly 25% drop in food waste as a result. Nestlé is using AI-powered visual inspection in its factories to catch product inconsistencies.

“One European grocer lifted revenue by two percent in six months – a significant jump in a low-margin industry – by combining fixed cameras and mobile devices to improve on-shelf availability,” Grisolia said. “Out-of-stocks were fixed before customers noticed.”

AI can be especially helpful with recalls.

“AI is being combined with blockchain tech to track goods at the batch level,” Mayham noted. “If there’s a contamination event, you can pinpoint the issue to a specific supplier or facility instead of recalling entire product lines.”

By using AI, businesses can train models on far more data sets than in the past.

“Large language models can read and contextualize structured data, like sensor outputs,” said Alex Sandoval, the CEO of Allie.AI, “to see how machines are performing, and unstructured inputs, like operator comments, and manuals … to show how operators responded historically. Reinforcement learning helps improve these models over time.”

An Eye Toward the Future

AI has already proven to be a game-changer in the business world – but only when applied with purpose.

“The companies seeing real impact aren’t the ones chasing trends; they’re the ones using AI to support the work that drives revenue, reduces cost, or eliminates the tasks their teams dread doing,” Calafell said.

AI has been proven to improve inventory accuracy, streamline planning, and help teams respond to issues in real time, whether it’s adjusting production when an operator doesn’t show up or rerouting a shipment before it becomes a delay.

That kind of responsiveness helps businesses shift from being reactive to resilient.

“We’re way past the ‘Is this real?’ stage,” Grisolia said of AI.

“What’s game-changing isn’t the AI alone; it’s the way it’s being embedded into everyday tools so that frontline workers can act in the moment,” she added. “The companies still confused are the ones chasing novelty over results.”

The most effective businesses along the supply chain plan for potential issues; when disruption inevitably hits, they’re often the only ones still shipping. AI helps businesses identify risk earlier, model different outcomes, and respond in real time.

“Whether it’s a weather delay, a tariff change, or a labor shortage, AI makes it possible to adapt with less chaos,” Calafell said. “Flexibility is the new efficiency.”