The food manufacturing industry’s most pressing challenges—labor shortages and high turnover, inconsistent quality, food giveaway, and constrained throughput—now have a proven solution. Chef Robotics has developed AI-enabled robots for meal assembly to flexibly automate production lines. To date, Chef has assembled over 79 million servings in real-world production environments. Food manufacturers who’ve implemented Chef’s automation solution have achieved 2-3x higher output, up to an 88% reduction in food waste, and up to 30% better portion consistency. Chef’s robotics-as-a-service business model lets manufacturers onboard robots without massive upfront capital investments.

Industry Challenges

The #1 Labor Crisis in the US

According to the Bureau of Labor Statistics, food preparation had 1.1 million unfilled jobs in 2023, the largest labor shortage in the U.S. The food industry also struggles with staff turnover rates exceeding 150% annually.

Why Traditional Automation Failed

Manufacturers have tried traditional automation equipment, such as depositors and dispensers, but nothing has delivered the required flexibility for high-mix food production. The fundamental problem: food ingredients are highly variable depending on how you prep, cook, and store them.

Traditional equipment is purely mechatronic and lacks the software intelligence to adapt. For high-mix manufacturers, fixed automation falls short in two ways: these systems cannot handle a large portion of a manufacturer’s SKU set, or even when they can (e.g., for sauces), the extensive cleaning time between runs makes them impractical. Either way, traditional automation fails to deliver value.

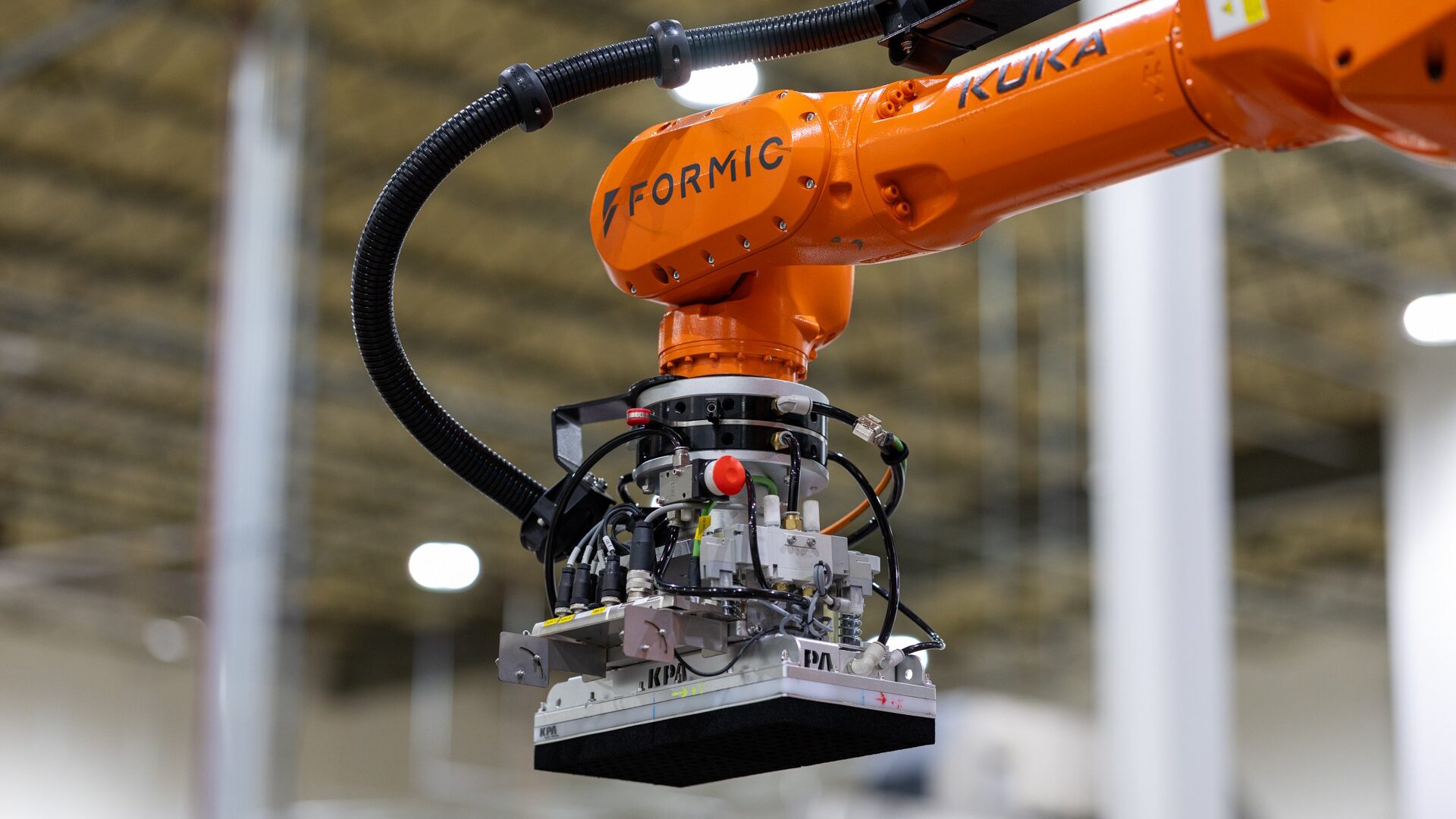

The Breakthrough: AI-Enabled Robots

Unlike traditional automation, Chef robots leverage computer vision and AI to adapt to food variability in real-time. These AI-enabled robots pick and place food ingredients from pans into trays (or compartments within trays) on meal assembly lines. By deploying them in real production environments, Chef turns its robots into data collection engines, and ChefOS uses this production data to continuously improve its AI models.

Ripple Effects of the Labor Shortage

When staffing runs short, manufacturers face compounding operational challenges:

- Inconsistency: When workers assemble meals manually, portion sizes vary, leading to quality issues and customer complaints.

- Food giveaway: To avoid underfilling and compliance issues, workers tend to overfill trays, resulting in costly per-unit margin erosion.

- High turnover: With soaring annual turnover rates, companies spend significant time and resources rehiring and retraining workers.

- Absenteeism and temporary dependency: When workers don’t show up or leave mid-shift, manufacturers have to rely on temporary labor, creating additional training burdens.

Chef robots deliver capabilities across multiple dimensions:

- As flexible as a worker: The robots are designed to provide the flexibility of a worker with the performance and reliability of a machine. They handle multiple SKUs with quick changeovers between production runs.

- Powered by AI: ChefOS intelligently picks based on each ingredient’s properties, pan topography, and daily prep variations. The robots work with various trays and conveyors while adapting to changes in conveyor speed, skewing, starts, and stops, achieving consistent weight and placement on every deposit.

- The same footprint as a worker: Each Chef robot occupies the same footprint as a worker and only requires 120V power, compressed air, and a Wi-Fi connection. This means Chef’s systems don’t require retrofitting—manufacturers just slide them onto the line and start running them.

- Easy to move: The robots are on casters, so workers can easily move them between lines during a shift, helping maximize utilization.

- Food-safe and easy to clean: Chef’s robotic module C-001748 is NSF-certified, confirming compliance with strict food-safety and cleanability requirements. The only parts that come into direct contact with food are the robot’s utensils and the pans.

- Human-friendly: Chef robots are collaborative and designed to work safely alongside workers per ISO/TS 15066:2016. Manufacturers can partially automate a line, enabling workers and robots to operate side by side.

Proven ROI for Customers

Today, Chef serves a dozen customers across the U.S. and Canada. For example:

- Cafe Spice has increased output by 2-3x and reduced food giveaway by 67%.

- Chef Bombay has improved consistency by 30%, increased labor productivity by 33%, and boosted throughput by 9%.

- Amy’s Kitchen has improved product consistency by 12% and increased labor productivity by 17%.

These results span hundreds of ingredients across more than 2,000 SKUs: starches (e.g., basmati rice, jasmine rice, and rotini), proteins (e.g., beef birria, diced chicken, shredded chicken, chorizo, and chili), leafy greens (e.g., romaine, iceberg, spinach, kale, and slaw), vegetables, curries, sauces, and cheeses.

No Future for Manual Meal Assembly

In the future, meal assembly will almost certainly be automated. The labor shortage isn’t a temporary challenge—it’s an existential threat to food manufacturing. In 10 years, even fewer people will want to work repetitive assembly jobs in cold production environments.

Food companies that have embraced AI and flexible automation early are already outperforming their competitors on quality, consistency, accuracy, throughput, and cost. Manufacturers who invest in automation today are building significant competitive advantages as the robots they utilize learn and improve over time.

The technology to make this shift exists today. The question is whether to lead or follow.