While mushrooms remain all the rage as a whole food ingredient, their physical characteristics are less than ideal for replicating whole cuts of meat. Enter mycelium – the root system from which mushrooms grow.

In properly controlled environments, mycelium can be cultivated into large slabs. As Scientific American reports, this process progresses rapidly: the accumulation of fibers becomes a visible sheet after a day or two, and a sizable slab weighing around two pounds within the course of a week.

Fungi-Based Benefits

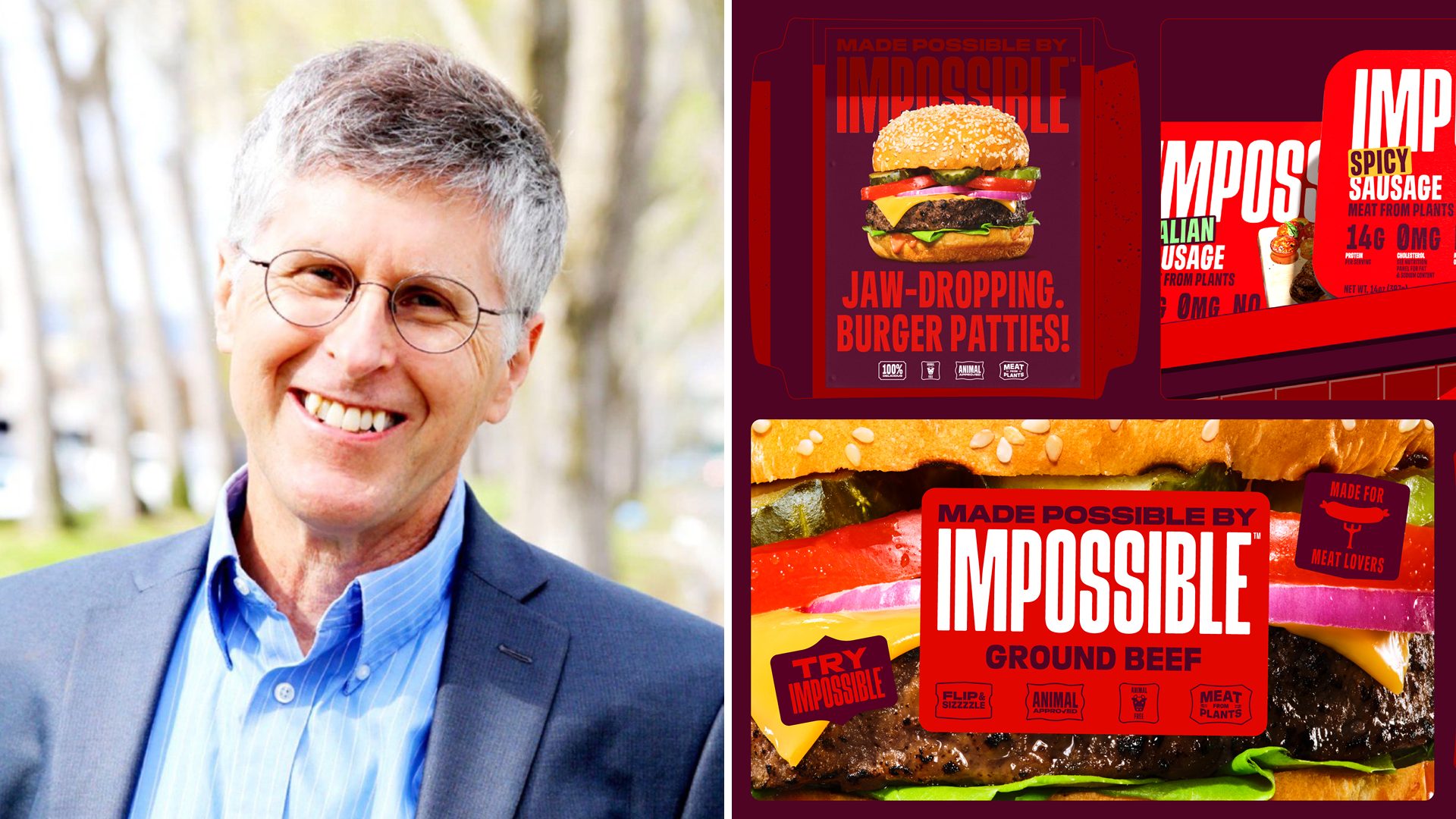

Mycelium-based products can offer solutions for plant-based food consumers in several areas primarily around nutrition and sustainability, David Benzaquen, founder and CEO of Mission: Plant told The Food Institute.

“As a whole food ingredient, mycelium-based products may appeal to consumers who prefer to consume alternative proteins that don’t require the processing associated with protein isolation,” said Benzaquen. “In addition, growing mycelium is very efficient and requires significantly less land, water, and energy than growing traditional field crops.”

The fungi is also said to improve the texture of plant-based products, which has been a key hurdle for producers in recent years.

“Mycelium from edible mushrooms offers ideal natural properties for product development, like a highly adaptable rich umami flavor, a naturally fibrous and juicy texture and minimal off-flavors,” Mazen Rizk, CEO of biotech company Mushlabs, told Food Navigator.

Mycelium also boasts a ‘balanced nutrient profile’, containing complete protein with all essential amino acids, prebiotic fiber, vitamins and minerals.

Recent Innovations

A growing number of companies are leveraging mycelium to enhance their plant-based offerings.

In July, Meati Foods raised $150 million in a Series C round backed in part by Cultivate Next, Chipotle Mexican Grill’s new venture fund.

The company plans to invest the funds in a new fermentation facility for its fungi-based platform — which is capable of producing ‘steaks’ and other whole cuts — as it gears up to support a “national omni-channel footprint by the end of 2023,” reported Food Navigator.

Meanwhile, MyForest Foods is set to open a new facility in upstate New York to help the company scale its mycelium-based bacon product, MyBacon.

As Fast Company reports, the new 120,000-square-foot infrastructure will have the capacity to produce nearly three million pounds of mycelium annually, and includes silos, a production facility, and what the company claims is the world’s biggest vertical farm for aerial mycelium – a method in which mycelium grows up and out of a substrate.

The vertical farm is very similar to those used for growing greens, where crops are stacked like towers for space and efficiency and kept at controlled conditions for optimal growth. However, for mycelia the space is kept dark, foggy, and dewy — like a misty morning forest. By tweaking these micro-conditions, the company can reportedly make sections of the slab denser than others, like a biological 3D printer.